Series connections are a fundamental concept in electrical engineering, commonly employed in various applications to achieve specific voltage or current requirements.

In a series connection, components are linked end-to-end, creating a single pathway for the flow of current. This guide will provide an in-depth understanding of series connections, outline their advantages and disadvantages, and offer a step-by-step guide on how to form a series connection.

Understanding series connections is crucial for anyone working with electrical circuits. By connecting components in series, you can control the flow of current and voltage in a circuit. This is particularly useful when you need to power multiple devices using a single power source.

One of the main advantages of series connections is that the total voltage across the circuit is the sum of the individual voltages of each component. This allows you to effectively increase the voltage in a circuit by adding more components in series.

However, series connections also have their disadvantages. Since the current has only one path to follow, if one component fails or is disconnected, the entire circuit will be interrupted. Additionally, the total resistance in a series circuit is the sum of the individual resistances of each component, which can limit the amount of current that can flow through the circuit.

To form a series connection, you simply connect the positive terminal of one component to the negative terminal of the next component, and so on, until all the components are connected in a single pathway.

This step-by-step guide will walk you through the process of forming a series connection, ensuring that you have a solid understanding of how it works and how to implement it in your own projects.

Table of Contents

- 1 How Series Connections Work

- 2 Advantages of Series Connections

- 3 Disadvantages of Series Connections

- 4 Step-by-Step Guide to Forming a Series Connection

- 4.1 Define Circuit Requirements

- 4.2 Choose Components

- 4.3 Gather Tools and Equipment

- 4.4 Safety Precautions

- 4.5 Component Orientation

- 4.6 Plan the Circuit Layout

- 4.7 Wire Preparation

- 4.8 Connect Components

- 4.9 Insulate Connections

- 4.10 Connect to Power Source

- 4.11 Power On

- 4.12 Measure Voltage (Optional)

- 4.13 Troubleshoot if Necessary

- 4.14 Document the Circuit

- 4.15 Conclusion

How Series Connections Work

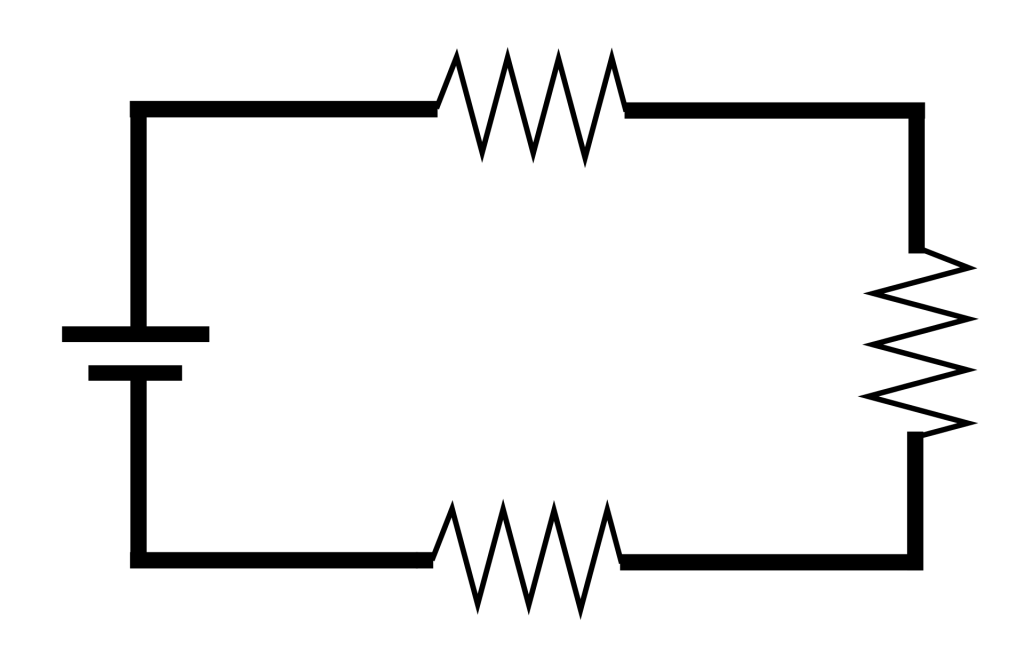

In a series circuit, components such as resistors, batteries, or other devices are connected sequentially, creating a single pathway for the flow of current.

This means that the current has only one path to follow, flowing through each component in the circuit.

One key characteristic of series connections is that the total voltage across the circuit is the sum of the individual voltages of each component.

This means that if you have multiple components connected in series, the voltage across each component adds up to give you the total voltage across the circuit.

For example, if you have two resistors connected in series, each with a voltage drop of 5 volts, the total voltage across the circuit would be 10 volts.

This voltage summation is a fundamental principle of series connections and allows you to effectively increase the voltage in a circuit by adding more components in series.

Another important aspect of series connections is that the current remains constant throughout the series. This means that the same amount of current flows through each component in the circuit.

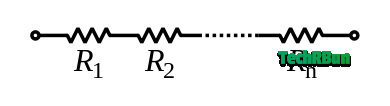

To calculate the total resistance in a series circuit, you simply add up the individual resistances of each component.

The formula for calculating the total resistance in a series circuit is:

Rtotal = R1 + R2 + R3 + …

Here, Rtotal represents the total resistance, and R1, R2, R3, and so on, represent the resistances of individual components. By calculating the total resistance, you can determine the amount of current that will flow through the circuit.

Understanding how series connections work is essential for anyone working with electrical circuits. It allows you to control the flow of current and voltage in a circuit, and it forms the basis for many electrical applications.

Advantages of Series Connections

Voltage Summation

Series connections offer several advantages that make them a valuable option in electrical circuits.

One key advantage is voltage summation. In a series circuit, the voltages across individual components add up.

This means that if you have multiple components connected in series, the voltage across each component adds up to give you the total voltage across the circuit.

This is particularly useful when higher voltage requirements need to be met.

For example, if you have two batteries connected in series, each with a voltage of 5 volts, the total voltage across the circuit would be 10 volts.

This voltage summation allows you to effectively increase the voltage in a circuit by adding more components in series.

Current Uniformity

Another advantage of series connections is current uniformity. In a series circuit, the current remains constant throughout.

This means that the same amount of current flows through each component in the circuit. This uniformity simplifies calculations and can be beneficial in applications where a consistent current is essential.

Ease of Troubleshooting

Additionally, series connections offer ease of troubleshooting. If one component fails in a series circuit, the entire circuit may be affected.

This makes it easier to locate the issue and identify the faulty component. By systematically testing each component, you can quickly pinpoint the problem and replace the faulty component.

Overall, the advantages of series connections, such as voltage summation, current uniformity, and ease of troubleshooting, make them a valuable choice in various electrical applications.

Disadvantages of Series Connections

While series connections offer several advantages, there are also some disadvantages to consider.

Increase in Total Resistance

One disadvantage is that as components are added in series, the total resistance of the circuit increases. This can be problematic in applications where low resistance is crucial for efficient operation. The increased resistance can lead to reduced efficiency and potential energy losses.

Circuit Disruption

Another disadvantage of series connections is the impact of component failure. In a series circuit, if one component fails, the entire circuit may be disrupted.

This can be a disadvantage in systems where redundancy or failover capabilities are critical. The failure of a single component can result in the loss of functionality for the entire circuit, which can be inconvenient and costly to repair.

Higher Power Dissipation

Additionally, series circuits may experience higher power dissipation compared to parallel circuits. This means that more energy is converted into heat, leading to potential energy losses.

Higher power dissipation can also result in components getting hotter, which can affect their performance and lifespan.

Despite these disadvantages, series connections still have their place in electrical circuits. It’s important to carefully consider the specific requirements of your application and weigh the advantages and disadvantages before deciding whether a series connection is the right choice.

Step-by-Step Guide to Forming a Series Connection

Define Circuit Requirements

To form a series circuit, it is important to clearly define the circuit requirements. This involves determining the purpose of the circuit, the voltage requirements, and the types of components needed.

Firstly, consider the purpose of your circuit. Are you looking to power a specific device or create a specific effect? Understanding the purpose will help you determine the appropriate components and voltage requirements.

Next, identify the voltage requirements for your circuit. This refers to the amount of electrical potential difference needed to power the components. It is crucial to choose components that can handle the specified voltage without getting damaged.

Lastly, consider the types of components needed for your circuit. This could include resistors, bulbs, or any other devices you want to connect in series. It is important to verify the voltage and current ratings of these components to ensure they are compatible with your circuit requirements.

By clearly defining the purpose of your circuit, determining the voltage requirements, and selecting the appropriate components, you can ensure that your series circuit functions effectively and safely.

Choose Components

When forming a series circuit, it is crucial to carefully select the components that will be connected in series. This step involves choosing the appropriate resistors, bulbs, or any other devices that will be part of the circuit.

To begin, consider the specific requirements of your circuit and the purpose you defined earlier. Based on these requirements, identify the components that will best suit your needs. For example, if you are creating a lighting circuit, you may choose bulbs as your components.

Once you have identified the components, it is important to verify their voltage and current ratings. This ensures that the components can handle the electrical potential difference and current flowing through the circuit without getting damaged.

Take note of the voltage rating of each component and ensure that it matches the voltage requirements you determined earlier. Similarly, check the current rating of the components to ensure they can handle the expected current flow.

By carefully selecting components and verifying their voltage and current ratings, you can ensure that your series circuit operates safely and efficiently. Remember to consider the purpose of your circuit and choose components accordingly to achieve the desired outcome.

Gather Tools and Equipment

To successfully form a series circuit, it is essential to gather the necessary tools and equipment. This step ensures that you have everything you need to assemble the circuit accurately and safely.

Start by collecting the required tools, which may include wires, wire strippers, pliers, a soldering iron (if needed for soldering connections), solder, a multimeter, and safety equipment such as gloves and safety glasses. These tools will enable you to handle the components and make the necessary connections effectively.

Wires are crucial for connecting the components in a series circuit, so ensure you have an adequate supply of wires of the appropriate gauge. Wire strippers will come in handy for removing the insulation from the wire ends, allowing for proper connections.

If soldering is required for your circuit, make sure you have a soldering iron and solder. This will enable you to create secure and reliable connections between components.

A multimeter is a versatile tool that can be used to measure voltage, current, and resistance in the circuit. It is useful for troubleshooting and verifying the circuit’s performance.

Lastly, prioritize safety by wearing gloves and safety glasses to protect yourself from any potential hazards while working with the circuit.

By gathering the necessary tools and equipment, you will be well-prepared to proceed with the next steps of forming your series circuit.

Safety Precautions

Before you begin working on your series circuit, it is crucial to prioritize safety. By following a few key safety precautions, you can ensure a safe and secure working environment.

First and foremost, always make sure that the power source is switched off before starting any work. This will prevent any accidental electrical shocks or short circuits. Double-check that the power switch is in the off position and that there is no power flowing through the circuit.

Additionally, it is essential to identify and adhere to safety guidelines for working with electricity. Familiarize yourself with the specific safety recommendations provided by the manufacturer of your components and equipment. These guidelines may include wearing safety gloves and glasses, using insulated tools, and working in a well-ventilated area.

Furthermore, it is important to handle the components with care. Avoid touching any exposed metal parts while the circuit is powered on, as this can lead to electric shocks. Always handle the components by their insulated parts and avoid placing them on conductive surfaces.

By taking these safety precautions, you can minimize the risk of accidents and ensure a safe working environment while forming your series circuit. Remember, safety should always be the top priority when working with electricity.

Component Orientation

When forming a series circuit, it is crucial to pay attention to the orientation of each component. This involves identifying the positive and negative terminals of each component. While some components, such as resistors, may not have polarity, others like LEDs do.

To ensure proper component orientation, start by examining each component and locating the positive and negative terminals. These terminals are usually indicated by markings or symbols on the component itself. For example, LEDs typically have a longer leg that represents the positive terminal and a shorter leg for the negative terminal.

By correctly identifying the positive and negative terminals of each component, you can ensure that they are connected in the right order within the series circuit. This is important because in a series circuit, the current flows through each component in a sequential manner. Connecting components with the wrong orientation can disrupt the flow of current and prevent the circuit from functioning properly.

So, before connecting the components in your series circuit, take the time to identify the positive and negative terminals of each component. This will help you ensure that the circuit is properly oriented and ready for the next step in the process.

Plan the Circuit Layout

When forming a series circuit, it is essential to plan the layout of your circuit before connecting the components. This involves determining the order in which the components will be connected and ensuring that the positive terminal of one component is connected to the negative terminal of the next.

To plan the circuit layout, start by considering the flow of current. In a series circuit, the current flows through each component in a sequential manner. Therefore, it is crucial to connect the components in the correct order to maintain the flow of current.

One way to plan the circuit layout is by drawing a schematic diagram. This diagram will help you visualize the circuit and ensure that the components are connected in the desired order. You can use symbols to represent each component and indicate the direction of current flow.

Another consideration when planning the circuit layout is the physical arrangement of the components. Depending on the available space and the size of the components, you may need to position them in a specific order to ensure proper connections.

By carefully planning the circuit layout, you can avoid confusion and ensure that the components are connected correctly. This will help you create a functional series circuit that meets your requirements.

Remember to gather the necessary tools and equipment before proceeding to the next step of wire preparation.

Wire Preparation

Before connecting the components in a series circuit, it is crucial to properly prepare the wires. This involves cutting and stripping the wires to the appropriate lengths and removing the insulation to expose enough wire for secure connections.

To begin, gather the necessary tools for wire preparation, including wire strippers. These tools are designed to safely remove the insulation from the wires without damaging the conductive material inside.

Start by measuring and cutting the wires to the desired lengths. It is important to ensure that the wires are long enough to reach between the components while allowing for some flexibility.

Next, use the wire strippers to remove the insulation from the ends of the wires. Place the wire into the appropriate gauge slot on the wire strippers and squeeze the handles together. This will cut through the insulation and allow you to pull it away, exposing the bare wire underneath.

When stripping the wires, be careful not to cut into the conductive material. It is important to have a clean, undamaged surface for making secure connections.

Once the wires are cut and stripped, they are ready to be connected to the components in the series circuit. This step will be covered in the next section, “Connect Components.”

By properly preparing the wires, you ensure that they are ready for secure and reliable connections, which are essential for the proper functioning of the series circuit.

Connect Components

To form a series circuit, it is crucial to properly connect the components. This step ensures that the electrical current flows in a continuous loop, allowing the circuit to function as intended.

Start by identifying the positive and negative terminals of each component. The positive terminal is usually marked with a plus sign (+), while the negative terminal is marked with a minus sign (-).

Next, attach the positive terminal of one component to the negative terminal of the next using wires. This can be done by using connectors or soldering, depending on the type of components and the desired level of permanence.

If using connectors, choose the appropriate type for your components. Common connector types include banana plugs, alligator clips, and terminal blocks. Ensure that the connectors are securely attached to the terminals to prevent any loose connections.

Alternatively, if soldering is preferred, heat the soldering iron and apply a small amount of solder to the joint where the wires and terminals meet. This creates a strong and reliable connection.

Remember to connect the components in the correct order, following the desired circuit layout. The positive terminal of the first component should be connected to the negative terminal of the second component, and so on, until all components are connected in series.

By properly connecting the components, you ensure that the electrical current flows smoothly through the circuit, allowing for the desired functionality.

Insulate Connections

To ensure the safety and proper functioning of your series circuit, it is essential to insulate the exposed wires and connections. This step prevents short circuits and protects against electrical hazards. There are several options for insulating materials, including electrical tape and heat shrink tubing.

Electrical tape is a common and easily accessible option for insulating connections. It is made of vinyl and has excellent insulating properties. To use electrical tape, simply wrap it tightly around the exposed wires and connections, ensuring that there are no gaps or exposed areas. This creates a protective barrier that prevents any accidental contact or short circuits.

Another option is heat shrink tubing, which provides a more secure and professional-looking insulation. Heat shrink tubing is made of a polymer material that shrinks when heat is applied. To use heat shrink tubing, slide it over the exposed wires and connections, making sure it covers the entire area that needs insulation. Then, use a heat source, such as a heat gun or lighter, to apply heat evenly to the tubing. As the tubing shrinks, it forms a tight seal around the wires and connections, providing excellent insulation.

Regardless of the insulation method you choose, make sure to carefully inspect the connections after insulating them. Ensure that there are no exposed areas or loose insulation. This will guarantee the effectiveness of the insulation and minimize the risk of any electrical issues.

By properly insulating the connections in your series circuit, you create a safe and reliable electrical system that can function optimally.

Connect to Power Source

To complete your series circuit, you need to connect it to a power source. This step provides the necessary electrical energy for the circuit to function. Start by identifying the positive and negative terminals of your power source. These terminals are usually labeled with a plus (+) and minus (-) sign respectively.

Using appropriate wires, connect one end of the series circuit to the positive terminal of the power source. This ensures that the current flows in the intended direction through the circuit. Make sure to secure the connection tightly to prevent any loose or unstable connections.

Next, connect the other end of the series circuit to the negative terminal of the power source. This completes the circuit loop and allows the current to flow continuously. Double-check that the connection is secure and properly aligned with the terminal.

It is important to note that when connecting the circuit to a power source, you should ensure that the voltage of the power source matches the requirements of your components. Using a power source with a higher voltage can damage the components, while a lower voltage may not provide enough power for them to function properly.

Once you have successfully connected the series circuit to the power source, you are ready to move on to the next step of powering on the circuit and checking for proper functioning.

Power On

To complete the series circuit, it is time to power on the circuit and check for proper functioning. Begin by turning on the power source, making sure it is securely connected to the circuit. Once the power source is activated, carefully observe each component to ensure they are illuminated or operating as expected.

This step is crucial as it allows you to verify that the circuit is functioning correctly. Take note of any components that are not lighting up or operating as intended, as this may indicate a faulty connection or a defective component. Troubleshooting these issues will be covered in a later section.

By powering on the circuit and observing the components, you can confirm that the electrical energy is flowing through the circuit as intended. This step is particularly important when working with complex circuits or circuits that involve sensitive components.

Remember to exercise caution when handling the circuit during this step. Avoid touching any exposed wires or components while the power source is on, as this can result in electric shock or damage to the circuit.

Once you have powered on the circuit and ensured that all components are functioning properly, you can proceed to the next step of measuring the voltage across each component, if desired. This optional step allows you to further analyze the performance of the circuit and ensure that the voltage across each component is within its specified limits.

Measure Voltage (Optional)

To accurately assess the performance of your series circuit, it is recommended to measure the voltage drop across each component. This optional step allows you to verify that the voltage across each component is within its specified limits. To accomplish this, you will need a multimeter, a versatile tool used for measuring electrical quantities.

Begin by selecting the voltage measurement function on your multimeter. Ensure that the range is appropriate for the expected voltage levels in your circuit. Carefully place the multimeter probes across the terminals of the first component you wish to measure. Take note of the voltage reading displayed on the multimeter.

Repeat this process for each component in your circuit, recording the voltage drop across each one. It is important to compare these readings to the specified limits provided by the component manufacturer. If any voltage readings fall outside of the specified range, it may indicate a faulty component or an issue with the circuit.

Remember to exercise caution when using a multimeter and handling live circuits. Always follow safety precautions and avoid touching any exposed wires or components while measuring voltage.

By measuring the voltage drop across each component, you can ensure that the electrical energy is distributed evenly throughout the circuit. This step provides valuable insights into the performance and health of your series circuit, allowing you to identify and address any potential issues.

Troubleshoot if Necessary

If the circuit is not functioning correctly, it is important to troubleshoot the issue to identify and resolve any problems. Start by checking for loose connections, as they can disrupt the flow of electricity and cause the circuit to malfunction. Ensure that all wires and components are securely connected and tightened.

Next, inspect the components for any signs of damage. Look for burnt or discolored areas, broken wires, or any other visible signs of wear and tear. If you find any damaged components, replace them with new ones to restore the circuit’s functionality.

If you have a circuit diagram available, refer to it to ensure that all components are connected correctly. Double-check the orientation of each component and verify that they are in the right position. Sometimes, a simple mistake in component orientation can cause the circuit to fail.

In addition, consider the power source. Make sure it is providing the correct voltage and that it is functioning properly. If necessary, test the power source with a multimeter to ensure it is delivering the expected voltage.

If you have gone through these troubleshooting steps and the circuit still does not work, it may be necessary to seek further assistance from an expert or consult additional resources. Troubleshooting can be a process of trial and error, but with patience and careful examination, most circuit issues can be resolved.

Document the Circuit

Documenting the circuit connections and creating a schematic diagram is an important step in forming a series circuit. This documentation serves as a reference for future troubleshooting or modifications. By having a clear and detailed diagram, you can easily identify the components and their connections, making it easier to diagnose any issues that may arise.

To document the circuit, start by labeling each component and its corresponding connection point. This can be done using labels or markers to ensure clarity. Take note of the wire colors and their respective connections as well.

Next, create a schematic diagram that represents the circuit layout. This diagram should include all the components, their connections, and the direction of current flow. Use symbols to represent each component, such as resistors, switches, and batteries, to make the diagram more concise and easier to understand.

Having a documented circuit and schematic diagram allows you to easily replicate the circuit in the future or make modifications if needed. It also helps in troubleshooting by providing a visual representation of the circuit’s structure. By referring to the diagram, you can quickly identify any potential issues and make the necessary adjustments.

In summary, documenting the circuit connections and creating a schematic diagram ensures that you have a clear reference for future troubleshooting and modifications. It helps in identifying and resolving any issues that may arise, making the circuit formation process more efficient and effective.

Conclusion

Series connections are a fundamental aspect of electrical engineering, providing a means to achieve desired voltage levels and ensure consistent current flow.

By forming a series connection, you can effectively combine multiple components, such as resistors or batteries, to meet specific voltage requirements.

This is particularly useful in electronic circuit design, where precise voltage levels are often necessary for optimal performance.

To form a series connection, follow the step-by-step guide outlined in the previous section. By carefully connecting the components in the correct sequence and verifying the total voltage and resistance, you can ensure that the series connection is properly formed and functioning as intended.

In conclusion, series connections are a valuable tool in electrical engineering, allowing for precise control over voltage levels and uniform current flow.

By understanding the advantages, disadvantages, and the process of forming series connections, you can confidently design and troubleshoot electronic circuits for a wide range of applications.